TESTS AND EFFICIENCY:

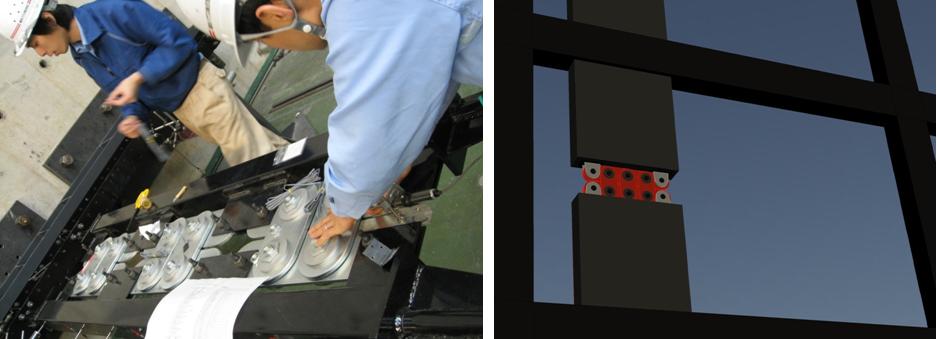

In April 2001, an international team of experts in earthquake engineering conducted an intensive experimental research program on a three-storey building equipped with Friction Damper Devices, FDD, at the advanced large-scale testing facility of National Center for Research on Earthquake Engineering, NCEER, Taiwan.

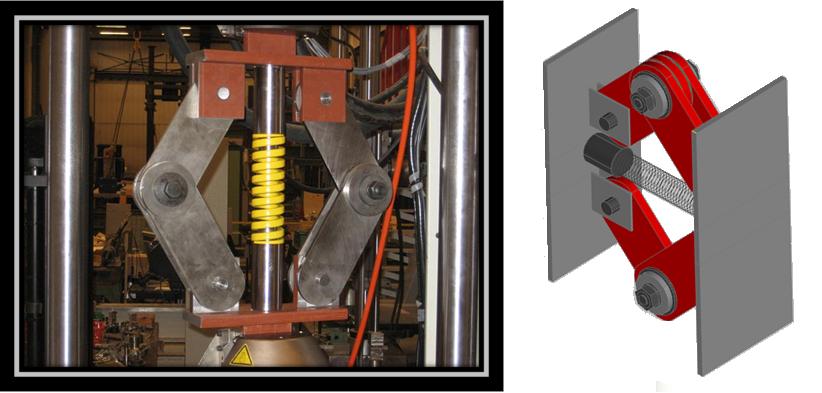

The test building is a steel moment-resisting frame structure with 3.0 m storey height and 4.5 m bay in the direction of shaking. Two FDD units were installed at each storey. Their characteristics were chosen based on extensive numerical analyses. A damper unit attached to the girder and instrumented for the testing is shown on the right photo.

The seismic response was evaluated using the shaking-table facility that simulated earthquake ground motions of far-field and near-fault types from the 1940 Imperial Valley - El Centro (USA), 1995 Kobe (Japan) and 1999 Chichi (Taiwan) events. All tests confirmed the remarkable efficiency of the damping system in reducing the lateral displacements and interstorey drifts of the test building.

GENERAL NOTES ON

- Installation

2-3 workers mounted the 6 dampers in the 3-storey frame in ONE DAY.

It was initially intended to perform 6 tests but due to the good performance 14 different tests were carried out within the same time period

No adjustments of the damping system were performed within 4 consecutive tests. This was a severe simulation of a series of aftershocks and could be also viewed upon as a possible situation at a site where due to a mistake of the installing staff damper parameters deviating from the design ones may be introduced

After the tests, the dampers and the bracing bars were removed within half a day - this fact implies that the devices can be easily replaced or inspected.

· Round plain steel bars were used with prestressing in order to provide a very economical technique instead of steel angle, channel or H shapes, typically used for brace members.

- Seismic performance and durability

The rigorous full-scale testing at the shaking table facility of NCREE (the second largest of this kind in the world) proved the excellent capacity of the damping system to significantly reduce the building vibrations as shown in table that follows

After all the 14 tests no damages occurred to the dampers, bracing bars, frame members and connections.

The dampers are in excellent condition and can be used for protection against future quakes.

The friction pad material also showed a very good performance and no scratches were observed on the sliding interfaces (see the photo below).

The mass of the dampers and the bracing was 0.15 ton - just 0.4% of the total test building mass and is expected to be much less in real buildings.

A full technical report will be published soon.

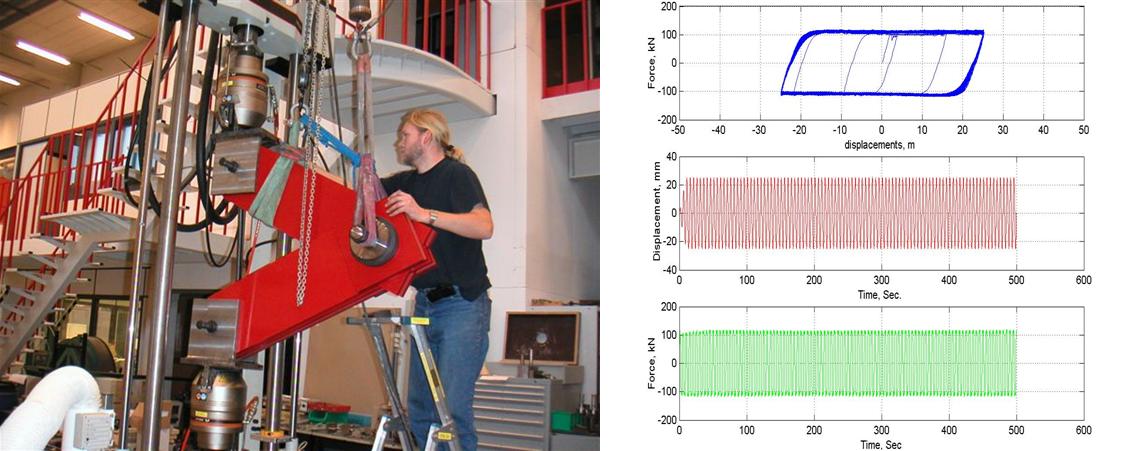

The damper had been tested intensively in order to evaluate the parameters influencing its performance.

Tests proved that the energy dissipated by the device is:

- Frequency independent for 2-7 Hz.

- Linearly dependent on clamping force in the bolt.

- Linearly dependent on displacement amplitudes.

- Very stable over many cycles.

- Very stable under large displacements

EFFICIENCY:

The first conclusion on the efficiency of FDD is derived from the reduction in the response displacement of frame structure under El Centro earthquake motion.

59% reduction in the lateral displacement

Another way to evaluate the efficiency of FDD system is through the energy balance concept. The figure below shows the energy terms, which are the strain energy, kinetic energy, viscous energy, damper dissipated energy and input energy.

Most of the Energy fed to the structure dissipated by the Damper Device.

The accuracy of the calculations is verified by comparing the sum of the energies mobilized (energy supply) with the input energy (energy demand). As shown, very good agreement is observed

OTHER DAMPER TESTS

Find additional pictures of tests in our test gallery: